- X-Ray detector diode size 0.8 mm, optional 0.4 and 0.2 mm

- X-ray source is 1 pc. high power x-ray generator, with max. 120kV (400W), variable in voltage + current, integrated closed oil cooling circuit

- Polyurethane belt white (FDA) conveyor

- Conveyor speed by product 30-60 m/min

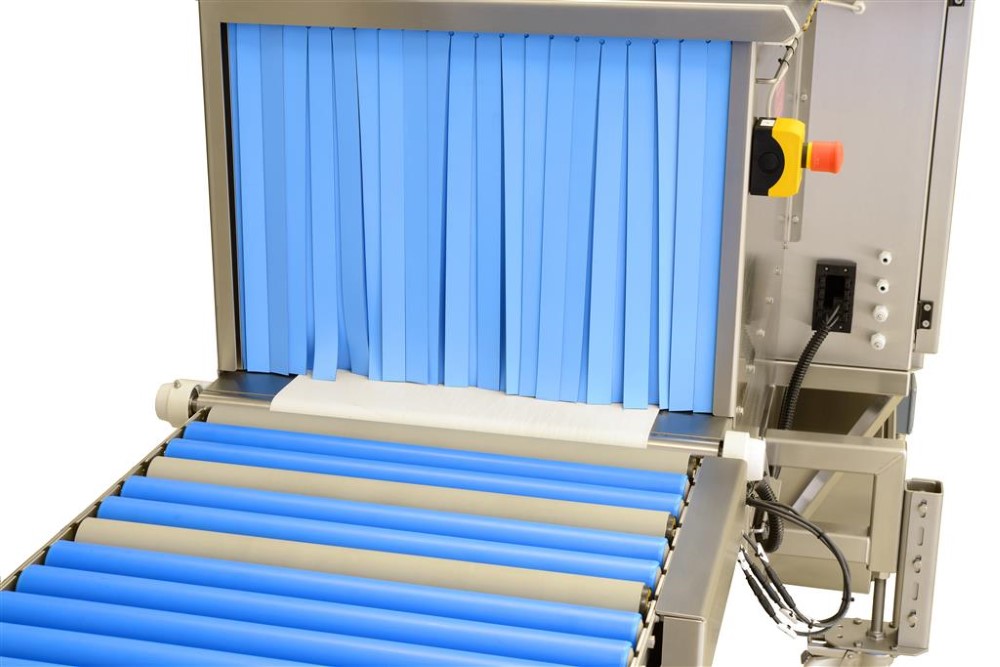

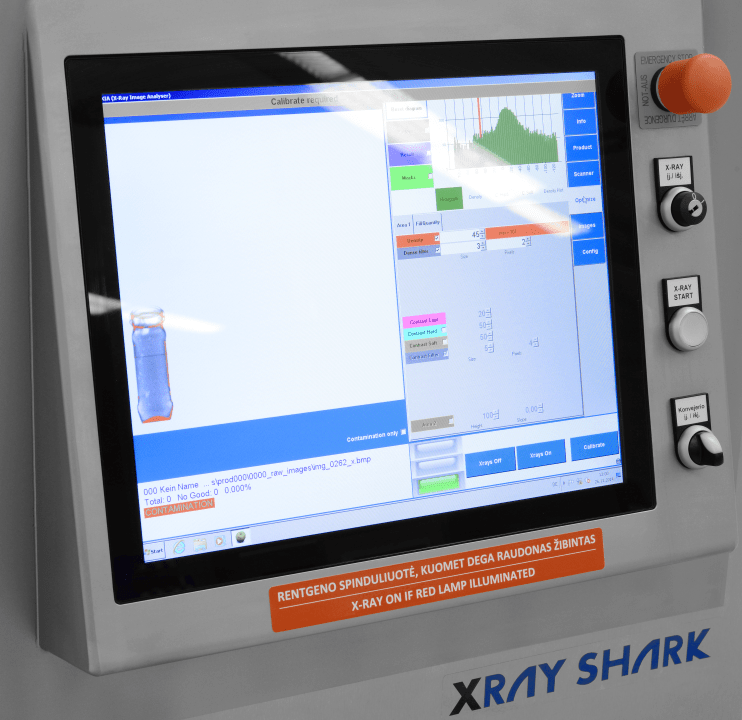

X-Ray inspection is sorting based on product density. An X-Ray inspection machine takes an image that is pixel based. The machine compares pixel density to stored pictures of “good” product to detect defects and contaminants. If the density of a product falls outside of acceptable range the reject mechanism removes the contaminated product out of the product flow.

X-Ray specifications vary per unit. Download the Datasheet for system details. Contact MPI to discuss your application.

- Optional reject systems include, but not limited to:

- Push Arm

- Air Blast

- Multiple Lane

- Flap at Belt End

- Additional options:

- Lockable Reject Bin

- Curtainless systems including extended infeed/outfeed tunnels