Protecting and Moving the World Through Innovation

Protecting and Moving the World Through Innovation

Support

24/7 Support

Standard business hours are 8 am to 5 pm (Eastern Time) with after hour emergency service … more

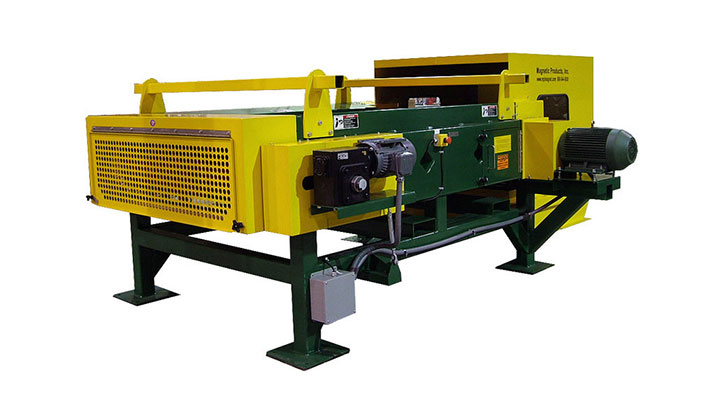

Equipment Rebuilds

MPI has the capability to offer rebuild services on all types of equipment … more

Installation and Startup

To ensure best performance, MPI recommends adding installation and startup services … more

Support

|

|

24/7 SupportStandard business hours are 8 am to 5 pm (Eastern Time) with after hour emergency service … more |

|

AuditingMPI has offered free magnet audits to our customers and potential customers for years …more |

|

Product RegistrationRegister the warranty on your products … more |

|

Equipment RebuildsMPI has the capability to offer rebuild services on all types of equipment … more |

|

Installation and StartupTo ensure best performance, MPI recommends adding installation and startup services … more |

|

Rental FleetMPI maintains a stock a rental fleet for a full range of custom applications … more |

|

|

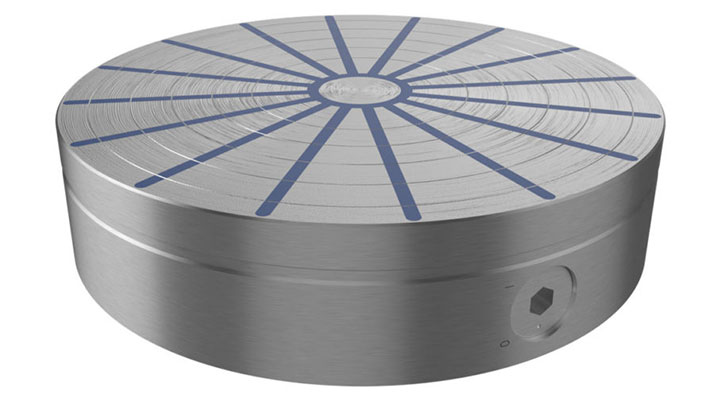

Non-Destructive TestingMPI offers confidential, non-destructive testing that helps…more |

|

Product TestingThe MPI test center features a wide range of metal control equipment …more |